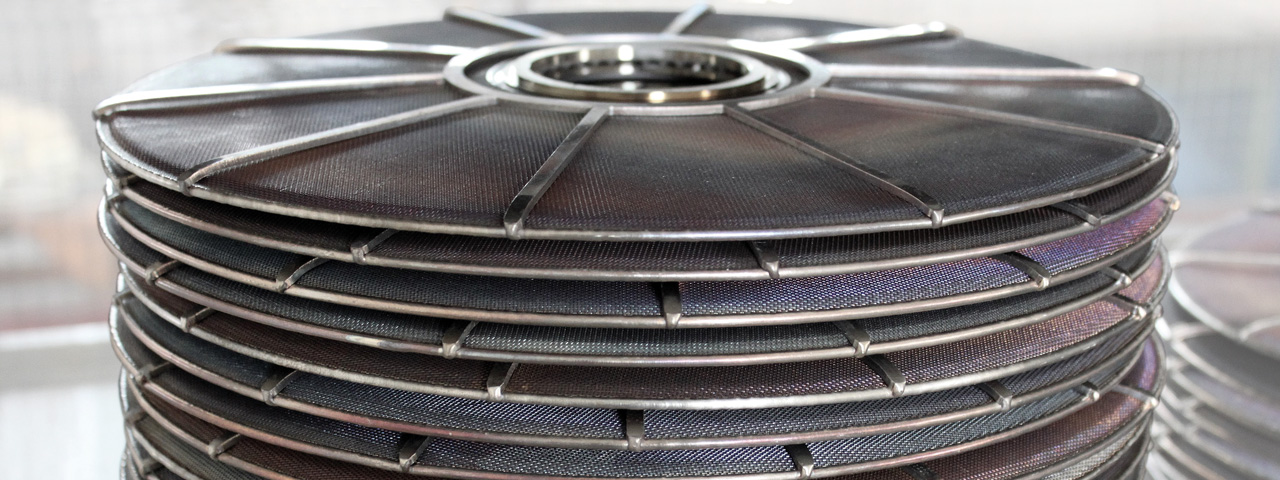

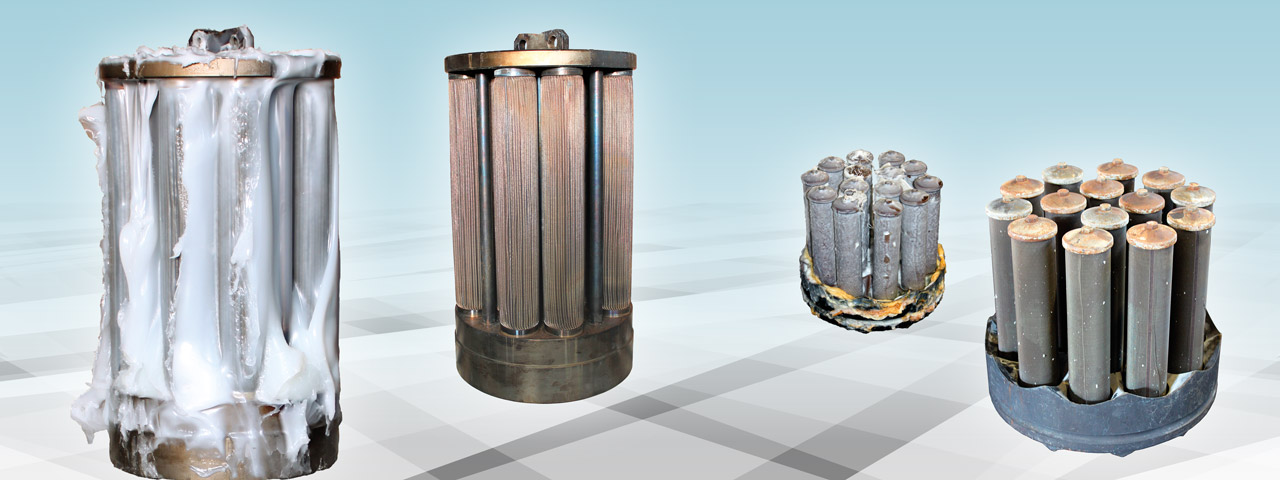

Thermal Cleaning of Candle Filters and Filter Disks

The gentle and repeatable cleaning of candle filters (filter candles) and filter disks (disc filter) as well as complete filter bundles is an important quality factor, among others, in fiber and film production. Polymers are removed in a single step – including possibly existing tacky particles – using (vacuum) pyrolysis (VACUCLEAN, MAXICLEAN). Inorganic remnants are removed using a select after-treatment method (high water pressure, ultrasound).

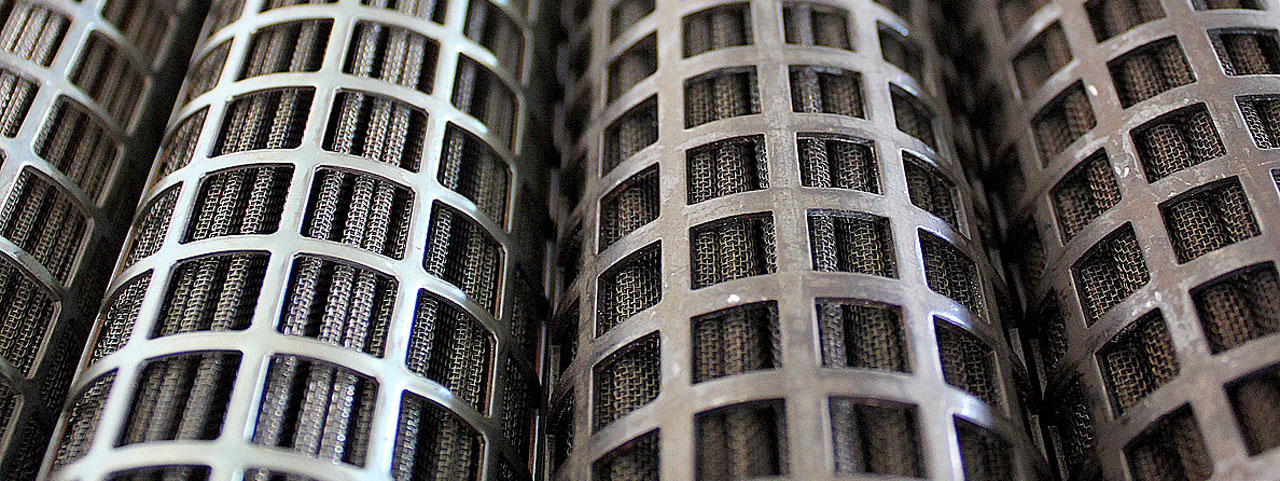

Cleaning of filters from screen changers

The gentle and repeatable cleaning of filters from screen changers is an important cost and quality factor in extrusion. Multiple cleaning is possible, depending on the type of polymer and the design of the filter screen. Polymers are removed in a single step. Inorganic remnants are removed using a select after-treatment method (high water pressure, ultrasound).

The INNOVACLEAN cleaning system, for example, takes only two to four hours to clean die plates. The cleaning system eliminates any risk of thermal or mechanical damage to the parts.

To enable us to respond to your questions or specific cleaning demands with custom-tailored information we ask you to please answer the inquiry form "Thermal Cleaning".